If there’s one game-changing innovation revolutionizing the energy-efficient home market, it’s Aerogel Thermal Insulation.

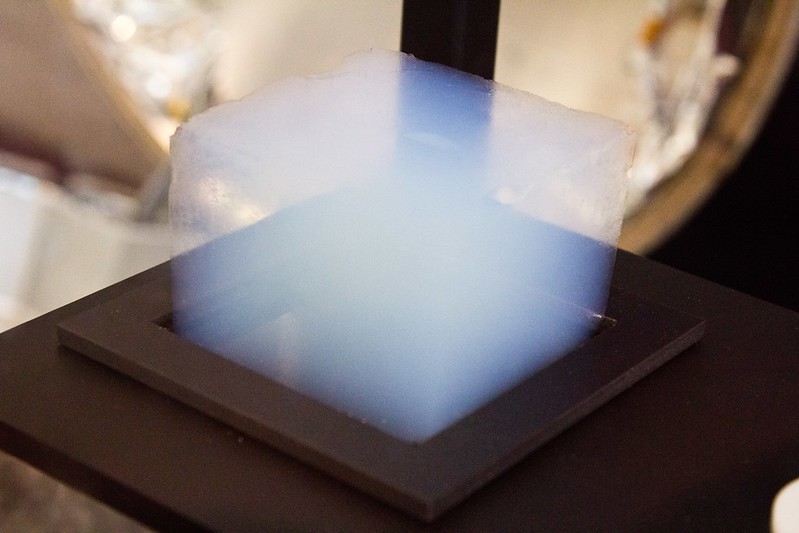

Often dubbed “frozen smoke,” aerogel is as light as air yet packed with insulating capabilities that have the potential to reshape the way we view home insulation.

So, what’s all the fuss about, and how exactly is this seemingly magical material leading the charge in energy-efficient homes? Let’s jump right in!

Aerogel Thermal Insulation – A New Innovation In Energy-Efficient Homes

Aerogel, a gel composed of a porous solid in which the liquid component has been replaced by gas, has long been known for its impressive thermal properties.

Its emergence as a mainstream insulation material, however, is relatively recent.

Boasting unparalleled insulating capabilities and an ultra-lightweight nature, aerogel thermal insulation is making waves in the world of energy-efficient homes.

The Science Behind Aerogel Thermal Insulation

Origins and Composition of Aerogel

Aerogel, often described as a “technological marvel,” boasts a rich history. Stemming from a gel, this material undergoes a meticulous process where the liquid component of the gel is replaced by a gas, typically air. This results in a solid with a highly porous structure. With up to 99% of its volume made up of air, this gives aerogel its feather-light characteristic.

Due to its unique makeup, aerogel possesses a complex network of interconnected nano-sized pores. These tiny pores, combined with the low solid content, make aerogel an extraordinary insulator.

Mechanics of Thermal Insulation

But how does aerogel, with its wispy and ethereal structure, manage to be such an effective insulator?

The magic lies in its ability to suppress the three modes of heat transfer: conduction, convection, and radiation.

- Conduction: The porous nature of aerogel impedes the motion of gas molecules through its structure. As these molecules are slowed down, so is the transfer of heat by direct contact.

- Convection: The size of the pores in aerogel is smaller than the mean free path of air molecules, limiting their movement and thus minimizing heat transfer by convection.

- Radiation: Aerogel’s translucent nature allows it to scatter infrared radiation, reducing heat transfer in this manner as well.

Together, these factors make aerogel a formidable barrier against heat transfer, making it a sought-after material in thermal insulation.

Benefits of Using Aerogel in Homes

1. Superior Thermal Performance

With the rising cost of energy and the increasing awareness of environmental concerns, efficient insulation is not just a luxury but a necessity. Homes insulated with aerogel maintain a consistent internal temperature, shielding inhabitants from extreme outdoor conditions. This means winters are warmer without excessive heating, and summers are cooler without over-relying on air conditioners.

2. Lightweight and Versatile

The inherent lightness of aerogel makes it incredibly adaptable. This means it can be utilized in parts of homes where traditional insulation might be too heavy or cumbersome. From walls to attics to crawl spaces, aerogel fits snugly without compromising the structural integrity of the building.

3. Sustainable and Eco-Friendly

Our planet is crying out for help, and every energy-saving measure counts. Aerogel insulation not only reduces the energy consumption of individual homes but also has a broader positive impact on the environment. By demanding less from our power grids, we reduce greenhouse gas emissions, making aerogel a green choice in every sense.

4. Long-Lasting and Durable

While the initial cost of aerogel might be a pinch point for some, its durability makes it a wise long-term investment. Resistant to moisture and decay, aerogel insulation remains effective for years, requiring minimal maintenance.

The Application Process

Preparation Stage

Before aerogel can work its magic, it’s vital to prepare the installation site. This involves cleaning the area, removing any previous insulation (if replacing), and ensuring there’s no moisture or debris.

Depending on where the insulation is to be placed, additional preparatory steps, such as patching holes or treating surfaces, might be necessary.

Installation Techniques

Aerogel comes in various forms suited to different applications:

- Aerogel Blankets: These are flexible and can be cut to fit various spaces. They’re ideal for wrapping around pipes or filling irregular gaps.

- Aerogel Panels: More rigid than blankets, these are perfect for flat surfaces like walls and roofs.

- Spray-On Aerogel: Still in development, this method would allow for an even more versatile application, covering intricate spaces with ease.

The chosen technique often depends on the specific requirements of the space in question and the homeowner’s preferences.

Post-Installation Care

One of the beauties of aerogel insulation is its low maintenance. Once installed, it does its job silently and efficiently. However, like all parts of a home, it’s good practice to inspect the insulation periodically for any signs of wear or damage, ensuring its continued performance.

Potential Challenges and Solutions

While Aerogel Thermal Insulation is revolutionary in many ways, there are still challenges to its adoption. Like any innovation, navigating its way from conception to widespread application is no straight path.

However, with challenges come opportunities for solutions.

1. High Initial Costs

Challenge: One of the major deterrents for homeowners considering aerogel insulation is the upfront cost. Aerogel, being a high-tech material, is priced higher than traditional insulation materials like fiberglass or foam.

Solution: While the initial investment is significant, aerogel’s superior insulating properties can result in considerable energy savings in the long run. Over time, the savings on heating and cooling bills can offset the upfront costs. Furthermore, as demand increases and production methods improve, the cost of aerogel insulation is expected to decrease.

2. Production Complexity

Challenge: The process to produce aerogel involves complex procedures and specific conditions, which can make mass production a challenge.

Solution: As with many technologies, advancements in production techniques and equipment could streamline the manufacturing process. Investment in research and development, and collaboration between industry leaders, can pave the way for more efficient and scalable production methods.

3. Limited Awareness

Challenge: Despite its remarkable properties, many homeowners and builders remain unaware of aerogel as an insulation option.

Solution: Increased marketing, educational campaigns, and collaborations with green-building initiatives can spread the word about aerogel’s benefits. Moreover, offering training programs for contractors and construction professionals can further promote its adoption in the building industry.

4. Brittle Nature

Challenge: Aerogels, especially in their monolithic form, can be brittle and susceptible to breakage, posing a challenge for certain applications.

Solution: Manufacturers have been developing aerogel composites, combining aerogel with other materials like fibers, to enhance its mechanical properties. These composites retain the insulating properties of aerogel while being more resilient to physical stress.

5. Dust Production

Challenge: Cutting or handling aerogel materials, especially blankets, can produce fine dust, which can be a concern for installers or homeowners.

Solution: Improved protective measures, like wearing masks and goggles during installation, can protect workers. Additionally, ongoing research aims to develop aerogel materials with reduced dust production.

6. Limited Supplier Base

Challenge: With aerogel being a relatively new material in the home insulation market, there are limited suppliers, which can sometimes result in supply chain disruptions.

Solution: Encouraging new entrants in the aerogel production market, perhaps through incentives or subsidies, can increase competition and stabilize supply. A more diverse supplier base also promotes innovation, potentially leading to even better aerogel products.

Understanding Aerogel’s Thermal Conductivity

When considering a new material or technology, especially something as crucial as home insulation, hard numbers, and statistics can provide clarity.

Here, we’ll look at aerogel thermal insulation through a numerical lens, offering tangible insights into its performance and impact.

Thermal Performance Metrics

The thermal resistance of a material, often called its “R-value,” is a measure of its insulating capability. The higher the R-value, the better the material is at insulating.

| Property | Aerogel | Traditional Fiberglass | Polyurethane Foam |

|---|---|---|---|

| R-value per inch | ~10.3 | ~2.2-4.5 | ~5.6-8 |

| Density (kg/m³) | ~200 | ~12-48 | ~32-96 |

| Thickness needed for R-13 insulation (inches) | ~1.26 | ~2.9-5.9 | ~1.64-2.32 |

Note: Values are approximate and can vary based on specific product formulations and conditions.

From the table, it’s evident that aerogel offers a superior R-value per inch compared to traditional insulating materials. This means that less material is required to achieve the same insulating effect, leading to slimmer walls and more usable space inside homes.

Cost Implications

While the performance of aerogel is outstanding, the cost is a significant factor for homeowners. Let’s break down the numbers.

| Factor | Aerogel | Traditional Fiberglass | Polyurethane Foam |

|---|---|---|---|

| Cost per square foot (approximate) | $1.50-$2.00 | $0.40-$0.70 | $1.00-$1.50 |

| Lifetime (years) | ~40 | ~10-25 | ~15-30 |

Note: Costs can fluctuate based on regional factors, brand, and specific product variations.

While aerogel has higher initial costs, its extended lifespan can result in long-term savings.

Environmental Impact

With rising concerns about the environment, understanding the ecological footprint of our choices is vital.

Here’s how aerogel measures up.

| Environmental Factor | Aerogel | Traditional Fiberglass | Polyurethane Foam |

|---|---|---|---|

| Energy savings over 10 years (for a 2000 sq. ft home) | ~60% reduction | ~20% reduction | ~40% reduction |

| Greenhouse gas emissions (during production) | Low | Moderate | High |

Note: The figures presented are approximations, and the actual impact can vary based on numerous factors.

The table underscores the superior energy savings homeowners can achieve with aerogel, leading to a smaller carbon footprint and reduced energy bills.

Aerogel Insulation Coating – How It Works

Aerogel insulation coating is a groundbreaking solution in the world of thermal insulation. Instead of bulky materials, this technology uses a thin layer of aerogel-infused coating. This coating can be applied like paint, adhering to various surfaces.

Once applied, the aerogel particles within the coating act as micro-insulators. They reduce the transfer of heat, providing impressive insulation with just a thin layer.

Its ease of application and versatility make aerogel coating a popular choice for retrofitting older structures or for use in areas where traditional insulation isn’t feasible.

Aerogel Pipe & Wall Insulation – Getting Started

Aerogel insulation isn’t limited to walls and roofs; it’s also an excellent choice for pipes. Pipes, especially in industrial settings, can be sources of significant energy loss if not insulated effectively.

To start with aerogel pipe insulation, one usually begins by selecting the right product. Aerogel comes in various forms, like blankets or wraps, tailored for pipe insulation. These wraps are wrapped around the pipe, often with a protective outer layer to shield against environmental factors.

For wall insulation, professionals often use aerogel panels or boards. They offer exceptional thermal resistance in a slim profile, maximizing interior space. Whether for pipes or walls, aerogel insulation promises a future of enhanced energy efficiency and comfort.

Key Takeaways

Aerogel Thermal Insulation is no passing trend. Its unparalleled thermal performance, coupled with a host of additional benefits, makes it a formidable contender in the insulation market.

As we strive for more sustainable living solutions, aerogel emerges as a beacon of hope, promising comfort, energy savings, and a brighter future for our planet.

I’m Thomas, the owner of SustainableWave. Passionately promoting a sustainable planet. With experience in various eco-roles, I’ll share green tips, sustainability hacks, and personal eco-journeys on my blog.