Hey, have you ever taken a moment to think about the life cycle of that glass bottle you’re holding? From its creation to its eventual recycling or disposal, the journey of a glass bottle is actually quite fascinating.

Glass bottles can take up to 1 million years to decompose in the environment, making recycling them crucial for ecological sustainability.

We come across them every day. From milk jugs to beer bottles, glass containers have been a part of human life for millennia. They’re durable, recyclable, and, let’s face it, there’s a certain charm about drinking from a glass bottle, right?

The Raw Materials for Glass and Their Origins

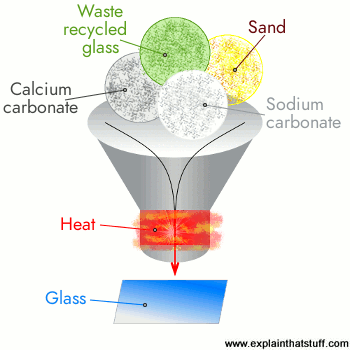

The story of the glass bottle starts with the meticulous selection and combination of raw materials.

Each of these ingredients, sourced from various parts of our planet, contributes unique properties to the final product.

Sand

The heart and soul of any glass are silica sand. Predominantly composed of silicon dioxide, this type of sand is the primary raw material in glass production. Vast deposits of silica sand are mined from beaches, riverbeds, and quarries worldwide. It provides the glass with its transparency and hardness.

Soda Ash and Limestone

Soda ash, scientifically known as sodium carbonate, plays the role of a fluxing agent. Mined from trona ores or produced synthetically, soda ash helps lower the melting point of the sand, thereby making the glass-making process more energy-efficient.

Limestone, a sedimentary rock composed mainly of calcium carbonate, is another critical ingredient. Crushed limestone, when added to the melt, imparts durability to the glass. This ensures our bottles and containers can withstand daily wear and tear.

Other Minor Ingredients

Various trace elements and compounds are added to the mix to customize the properties of the glass. Alumina enhances the chemical resistance of the glass, while ferric oxide can be used to produce amber or brown-colored bottles, which protect the contents from harmful UV rays.

Other components, like barium and magnesia, can also be introduced to fine-tune the glass’s refractive index or brightness.

The Manufacturing Process of Glass Bottles

Once the raw materials are sourced and prepared, they undergo a series of meticulous processes to transform them into the glass bottles we’re so familiar with.

Melting and Refining

The mixed raw materials are introduced into a furnace, where they are melted at temperatures ranging from 1700°C to 2000°C.

This fiery cauldron transforms the gritty sand and other ingredients into a homogeneous molten mass.

During this phase, any impurities or bubbles present are eliminated to ensure the final product’s clarity and quality.

Forming

The next stage is where the molten glass gets its shape. There are two primary methods:

- Blow and Blow Method: In this method, a gob of molten glass is dropped into a mold, and compressed air is used to blow it into the shape of the desired bottle. This technique is commonly used for producing narrow-necked bottles.

- Press and Blow Method: Here, the gob is pressed into the shape of the bottle’s base and body in the initial mold. Compressed air is then introduced in a secondary mold to form the neck of the bottle. This method is suitable for wide-necked bottles and jars.

Annealing and Cooling

This process might seem simple, but it’s vital to ensure the glass bottles’ quality. Once formed, the glass bottles are still susceptible to internal stress due to temperature differences.

Annealing involves heating the bottles to a specific temperature and then gradually cooling them. This controlled cooling ensures the glass is stress-free, uniform in thickness, and more resistant to breakage.

Life Cycle of Glass Bottles

The life of a glass bottle is a remarkable journey. It begins with an idea and a design, carefully crafted to meet specific needs. This design is then transformed into tangible bottles, ready to be filled and sealed.

Once produced, these bottles travel far and wide, reaching consumers across the globe. They serve as reliable containers for a multitude of products, from fizzy beverages to essential oils. Their sturdy nature ensures they can be used and reused multiple times without loss of quality, embodying the principle of sustainability.

But the story doesn’t end when the bottle is emptied. Glass, being 100% recyclable, finds a new purpose in the cycle. The empty bottles are collected, melted down, and reshaped, beginning their journey anew. This ability to be continuously recycled without degradation makes glass an environmentally friendly choice.

Moreover, many bottles find second lives in creative repurposing projects. They may transform into vases, lanterns, or even building materials. This adaptability further extends their lifecycle, reducing waste and promoting a circular economy.

Glass Bottle Usage in Everyday Life

Glass bottles are an integral part of our daily lives, seamlessly blending into various aspects. Whether you’re grabbing a cold soda on a hot day, enjoying a chilled beer with friends, or simply hydrating with water, the experience is often enhanced when the beverage is contained in a glass.

The transparency of clear glass bottles allows us to see the purity of the liquid inside, enticing our senses even before the first sip. And it’s not just about beverages. Think of your kitchen pantry. Jars filled with jams, pickles, and sauces are often made of glass, ensuring the contents stay fresh and unaltered by external factors.

This preservation quality extends to the medical world as well. Essential oils, syrups, and various medicines find a safe home in glass bottles, preserving their efficacy and purity.

So, the next time you reach for a product housed in a glass bottle, take a moment to appreciate its omnipresence in enriching and simplifying our daily routines.

Glass Bottle Recycling

Recycling glass bottles is a marvel in sustainable practices. Picture this: each discarded bottle you throw into the recycling bin embarks on a remarkable journey, proving that one man’s trash is indeed another man’s treasure.

The process kicks off with collection. From curbside pickups to recycling centers, our used bottles congregate, waiting for their next phase. The mingling of old bottles from various households almost feels like a reunion, doesn’t it?

Once gathered, these bottles head for processing. Here, they undergo thorough cleaning to remove any residues or contaminants. It’s akin to preparing for a fresh start or a second chance at life.

The cleaned bottles are then crushed into what is known as a cullet. This stage transforms them into raw materials, ready for remanufacturing. It’s like the phoenix, ready to rise from its ashes.

The magic happens during remanufacturing. The crushed cullet gets melted and reshaped, birthing new glass bottles. Old bottles reincarnated, ready to serve once again.

I’m Thomas, the owner of SustainableWave. Passionately promoting a sustainable planet. With experience in various eco-roles, I’ll share green tips, sustainability hacks, and personal eco-journeys on my blog.